Your Complete Rotational

Moulding Resource

Advances in rotational moulding techniques are introducing this cost-efficient and flexible product development and production process to numerous industries. In this dynamically evolving environment, it pays to work with a company that has proven capabilities in all critical areas, from design and specification through to producing the finished product. With the largest machines in New Zealand, we can produce parts ranging from 100mm – 7.5 m, allowing us to bring the unique benefits of rotational plastics to your project.

Galloway Brands

Galloway Group’s aligned companies rely on ground-breaking designs and the cost-efficiencies of rotational moulding for their success.

Why Choose Rotational Plastics

Galloway Group is proud that virtually all our waste products are 100% recyclable. The Resins we use in our production are 100% recyclable and with a recycling plant located opposite our factory in East Tamaki disposal transportation is negligible.

Galloway Group has been certified by the Eco Smart programme and continue to look at ways of improving our carbon footprint. All products at the end of their useful life can be recycled and the resin produced is used for many applications.

COST EFFECTIVE

The tooling cost is much lower, making the process ideal for smaller production runs.

ANY SIZE

There are virtually no size limitations on the products that can be produced.

UNIFORM

Extremely uniform thickness for the product walls, even at the corners.

COMPLEX SHAPES

Complex shapes can be included in the moulding process for cost savings.

STRONG & DURABLE

Rotational plastics are renowned for their durability, UV resistance, colourfastness.

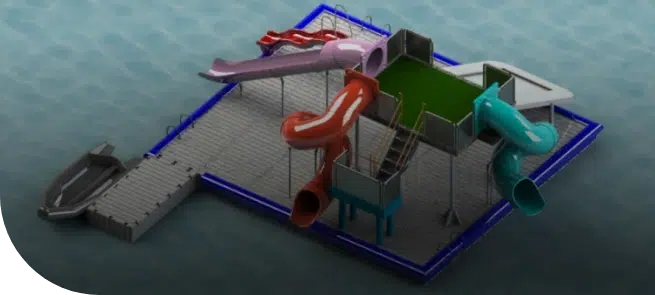

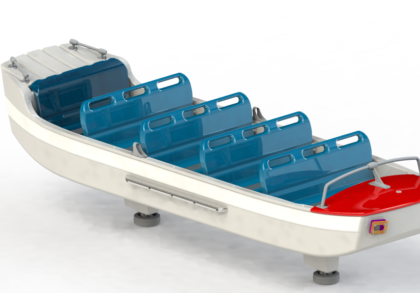

Featured Projects

Galloway Group’s aligned companies rely on ground-breaking designs and the cost-efficiencies of rotational moulding for their success.